A numerical study on T-reduce junction flow distribution

DOI:

https://doi.org/10.59190/stc.v2i2.208Keywords:

CFD, Correlation Equation, Junction, T-Reducer, VenturiAbstract

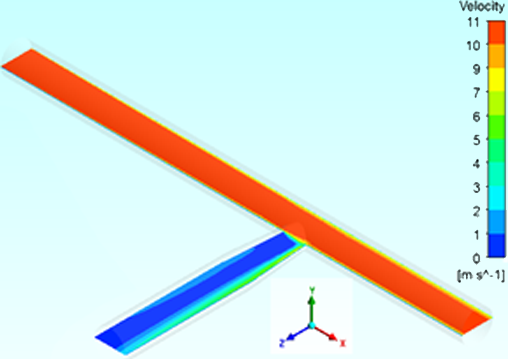

Although many manifold shapes have been studied, research on venturi-shaped manifolds with holes smaller than the inner diameter of the pipe, hereinafter referred to as T-reducer, has so far not been found. This research studies the effect of hole diameter and Reynolds number on the debit that comes out of the branch pipe. The venturi hole diameter is varied from 40% to 80% of the main pipe diameter, while the bulk velocity is varied from 2 to 10 m/s. The research started by creating a 3D T-reducer model, followed by CFD simulation using Fluent software. From the simulation results, curve fitting is performed using multiple regression to obtain an equation which is the correlation of dimensionless numbers. The maximum difference between the flow coefficient obtained from the curve fitting equation and the CFD simulation results is 3.35%.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Haryadi Haryadi, Sugianto Sugianto, Ali Mahmudi, Radi Suradi Kartanegara

This work is licensed under a Creative Commons Attribution 4.0 International License.