Improving homogeneous chamber temperature of biomass dryer by automatic air controlling system

DOI:

https://doi.org/10.59190/stc.v1i3.198Keywords:

Automatic System, Biomass-Fuel Dryer, Chamber, Homogenous, TemperatureAbstract

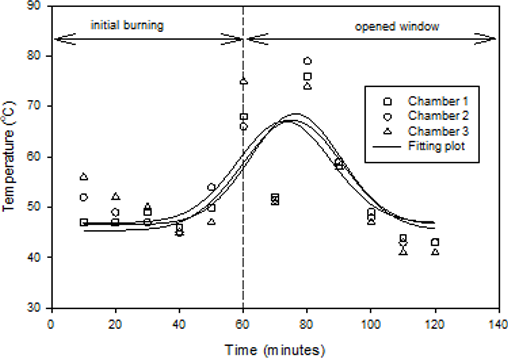

Biomass dryer (BD) was a useful device to improve the time efficiency of drying activities in traditional systems. The fuel source of biomass can be obtained from agricultural wastes, such as corn cobs and coconut shells. The classic problem of BD is the inhomogeneous temperature inside the chambers, which leads to damage to the product if the air circulation is not controlled. This study utilizes an electronic controller to automatically manage airflow by a fan and open the window to obtain a homogenous temperature in each chamber. The window will be opened instantly if the temperature inside the chambers exceeding 46°C. This testing sample product is a cracker, locally called ‘krupuk’. Cracker is made from tapioca flour and dried for several days after cutting processes. Our previous test successfully improves time efficiency in drying the post-harvest agricultural product. The proposed dryer consists of cabinet with 3 chambers, an open fire drum, a couple of automatic windows, and an electronic board as a controller. The resulting test shows a homogenous temperature average for the 3 chambers is 50°C.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Juandi Muhammad, Krisman Krisman

This work is licensed under a Creative Commons Attribution 4.0 International License.